UHMWPE slurry pipe

DRAGON UHMWPE pipe is made from Ultra High Molecular Weight Polyethylene with viscosity-average molecular weight of 2.0 millioin to 9.2 million g/mol. We manufacture the pipes with utilizing advanced extrusion technology. DRAGON’s UHMWPE pipes have been widely applied in the fields of dredging, mining, chemical industry, power plant, water supply, food industry, conveyor systems, etc.

Keywords:

Classification:

Description

DRAGON UHMWPE pipe is made from Ultra High Molecular Weight Polyethylene with viscosity-average molecular weight of 2.0 millioin to 9.2 million g/mol.

We manufacture the pipes with utilizing advanced extrusion technology.

DRAGON UHMWPE pipes have been widely applied in the fields of dredging, mining, chemical industry, power plant, water supply, food industry, conveyor systems, etc.

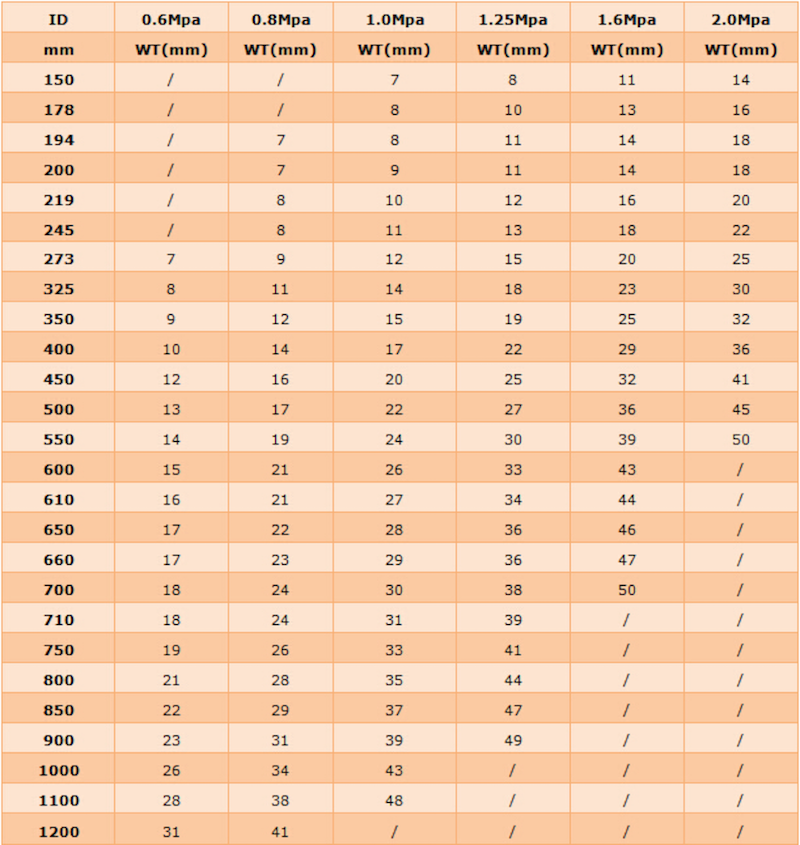

DN 30 to DN1200

Compare with conventional HDPE pipe, UHMWPE pipe has advantage as below:

1. Longer life time: the abrasion value is 4-7 times of HDPE pipe

2. Non Scaling: it has very smooth surface and self-lubricating property

3. High wear resistance and light weight means lower maintance cost, less down time.

4. Less frication loss:UHMWPE has friction coefficient of 0.05 (0.28 for HDPE), it means less friction, less pressure loss and greatly reduced energy input

Advantages of UHMWPE Pipe Over Steel Pipe:

40 times the abrasion resistance of steel .

8 times lighter than steel.

5 times lower coefficient of friction than steel.

The pressure loss of UHMWPE pipe is 1/10 of steel pipes and 1/7 of nylon pipes.

Application:

Mining

Mining pipes for Mineral sands mines; Mine Tailing lines; Mine concentration lines; Mineral mud conveying, Slurry transmission.

Dredging

Dredging pipe for dredging work, sediment transportation of the river, lake, sea port, wharf, etc

Previous Article

Next Article

Previous Article

Next Article

Recommended Products

Contact Us

Mobile/Wechat/WhatsApp: +86 188 6354 9177

Email: sales@dragonuhmwpe.com

Address: Xiangguang Economic Development Zone, Yanggu, Shandong, China

Postcode: 252300