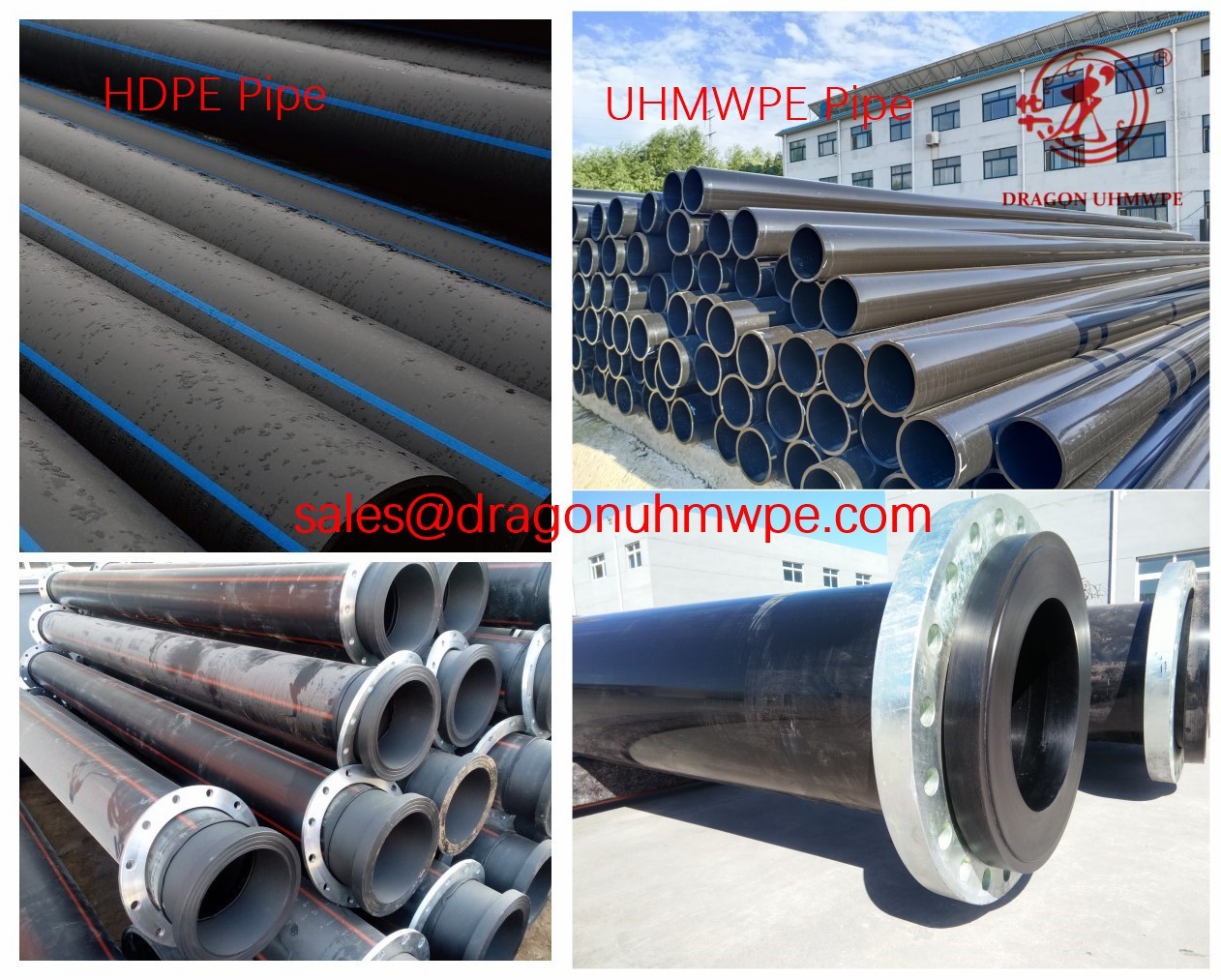

comparison between HDPE and UHMWPE pipe

2021-10-07 13:39

Comparison between HDPE and UHMWPE

|

HDPE VS UHMWPE |

|

|

HDPE is high density polyethylene |

UHMWPE is ultra-high molecular weight polyethylene |

|

Structure |

|

|

HDPE has short polymer chains compared to UHMWPE |

UHMWPE has very long polymer chains |

|

Molecular weight of polymer chains |

|

|

The polymer chains of HDPE has low molecular weight than UHMWPE |

UHMWPE polymer chains have very high molecular weight |

|

Molecular weight of raw materials |

|

|

HDPE with less than 500,000 g/mol |

UHMWPE above 2000,000 g/mol; according to standard QB/T 2668.1-2017 Ultra-high-molecular weight polyethylene (PE-UHMW) pipes |

|

Fabrication |

|

|

HDPE can be shaped and welded using thermoplastic equipment (HDPE straight pipe is thermal welded onto HDPE stub) |

UHMWPE can be fabricated and machined, while not suited to forming specific shapes and welding. (UHMWPE straight pipe get stub from the pipe itself through infrared heating) |

|

Pipe Production speed |

|

|

HDPE pipe: Approximately 8000~10000kgs/extrusion machine/day. Vary from pipe size and extrusion machine capacity |

UHMWPE pipe: Approximately 200~300kgs/extrusion machine/day. Vary from pipe size and extrusion machine capacity. |

|

Application |

|

|

HDPE application |

UHMWPE application |

|

3D printing, can be shaped into any type of product that may need a sturdy and dense foundation |

Machined into components like wear strips, chain guides, bumpers, bearings, guide rails, construction surface, outrigger pads. |

|

water pipeline, sand dredging pipeline, mineral slurry transport liner. |

Marine pile sleeve, dock fenders |

|

|

High wear and corrosion resistance application at mineral slurry transport, sea water dredging, brine saline water transport, chemical pipeline at power plant. |

Contact Us

Mobile/Wechat/WhatsApp: +86 188 6354 9177

Email: sales@dragonuhmwpe.com

Address: Xiangguang Economic Development Zone, Yanggu, Shandong, China

Postcode: 252300