Application Analysis of UHMWPE Pipe Fittings in Wet Desulfurization System for a power generation plant

2024-03-25 15:57

Application Analysis of UHMWPE Pipe Fittings in Wet Desulfurization System for a Power Generation Plant

In the wet desulfurization system of thermal power plant, the slurry conveying pipe and pipe fittings need to have excellent corrosion resistance and wear resistance due to its characteristics of the working medium. Through the use and detection of a new type of ultra-high molecular weight polyethylene (UHMWPE) pipe fittings for nearly 2 years, it is proved that the product has excellent corrosion resistance and wear resistance which can be used in the desulfurization slurry delivery system to replace the traditional stainless steel pipe, rubber lining and plastic lining pipe fittings, with reliable performance and obvious cost-effective advantages, it is worth promoting.

1. UHMWPE Overview

Ultra-high molecular weight polyethylene (UHMWPE) is a kind of excellent thermoplastic engineering plastic, its relative molecular mass is between 1.5 million to 10 million, holding excellent properties in impact resistance, wear resistance, self-lubrication, chemical corrosion resistance, healthy, non-toxic, environmental protection and so on, which is incomparable by other plastic. Ultra-high molecular weight polyethylene (P-UHMWPE) pipe fittings use 100% ultra-high molecular weight polyethylene resin, the product has excellent performances of ultra-high molecular weight polyethylene material, its mortar wear resistance is 5 ~ 7 times of stainless steel, it is resistant to a variety of corrosive mediums, meanwhile holding self-cleaning and non-scaling characteristics. The excellent performance of UHMWPE pipes and pipe fittings and the main technical parameters as shown in Table 1.

Table 1 Main Technical Parameters of UHMWPE Pipes and Pipe Fittings

|

Density/(g·cm - 3 ) |

Elongation at Break/% |

Longitudinal Retraction Rate/% |

Time of Oxidation Induction /min |

Mortar Wear Rate/% |

Impact Strength of Double Gap of Simple Support Beam/(kJ·m - 2 ) |

|

0 . 948 |

≥300 |

=0 . 5 |

≥100 |

=0 . 39 |

≥150 (sample type II) |

2. Status of Equipment

The 2x600 MW unit of A Power Generation company. (hereinafter referred to as Client) adopts limestone wet desulfurization process, using limestone (CaCO3) slurry as detergent, to wash the flue gas in the absorption tower, so as to remove SO2 in the flue gas. Gypsum fluid medium is acidic, pH value between 5.0 ~ 5.5, medium belongs to solid and liquid mixture, especially the fluid medium in the speed to the pipe fittings (size head, tee, elbow) wall by strong erosion, leading to its service life is too short, thus increasing the operating cost and the labor intensity of workers, there is also the risk of environmental pollution caused by slurry medium leakage. In order to improve its service life and improve the working environment, the power plant uses expensive 316L stainless steel pipe fittings, the result is still not satisfactory, in the harsh environment, the service life of straight pipe, elbow, size head and tee is usually only about 1 year. In order to completely solve the technical problem of short service life of straight pipe, elbow, size head and tee, since 2014, client has tried out a variety of new products, in August 2021, two pairs of UHMWPE elbows were tested (the elbow size is DN 100 mm, the bending radius is R = 250 mm, as shown in Pic 1), the original stainless steel pipe in this position was used for about 1 year, and the trial UHMWPE elbow is still in use today, and has been running as normal for more than 3 years, there is no obvious wear of the elbow wall, and the expected service life is 8 ~ 10 years.

Pic 1 UHMWPE Elbow

3. Test Position and Medium Characteristics

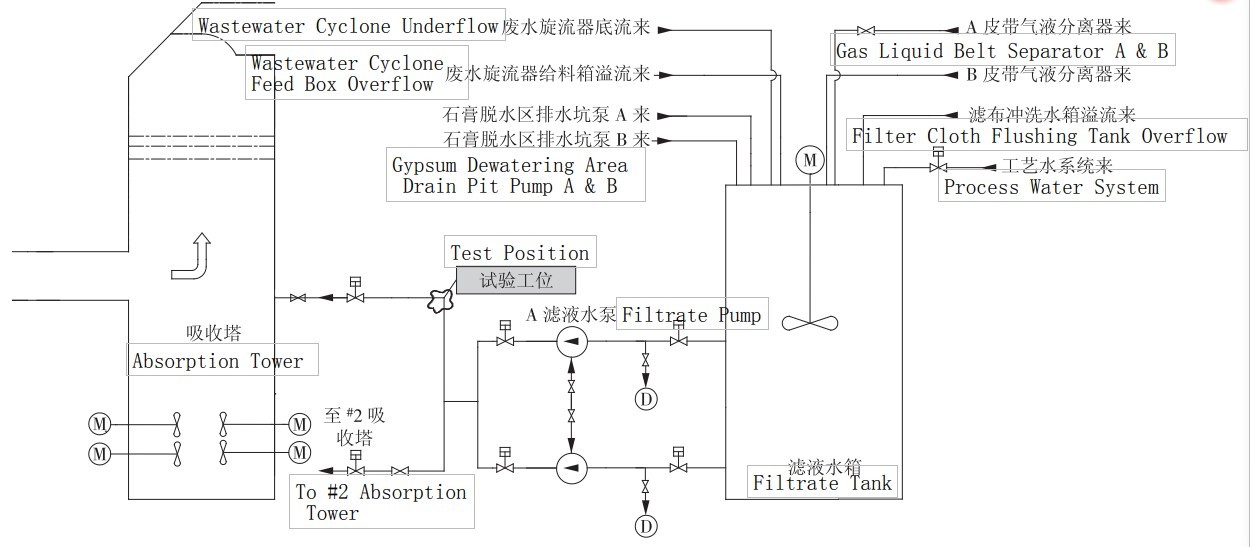

To verify the wear resistance of UHMWPE pipe fittings in the slurry system, this project practice selects an elbow in the filtrate water system as the Test Position, the flow of filtrate water system (including the Test Position) is shown in Pic 2

Pic 2 Filtrate Water System Process

As can be seen from Pic 2, when the desulfurization system is normally put into operation, the medium is the waste water source of the pulping and dehydration system, covering the bottom flow of the dehydrator, ball mill, cyclone overflow, ground washing water, etc. The characteristics of the medium are relatively complex, see Table 2 for details. In addition, the Test Position is the end of the system pipeline, which is directly connected to the Absorption Tower body. When the filtrate Water system is suspended, the water hammer impact phenomenon of the system pipeline is obvious. After long-term use of the original pipes and pipe fittings, there are some problems, such as high perforation rate, poor impact resistance of valves, and frequent leakage of tight flange surface.

Table 2 Medium Characteristics at the Test Position

|

Slurry Density/(g·cm - 3 ) |

Temp./℃ |

Pressure/kPa |

Particle Charateristics |

pH Value |

CI-Mass Ratio ( mg·kg - 1 ) |

|

1 . 05 |

43 |

385 |

Solid/Liquid Mixture |

6 . 8 |

8 |

Pic 3 UHMWPE Elbow Installation on Site

4. Application Analysis

4.1 Wear Performance Comparison

The test elbow was installed in August 2021. In order to fully grasp its wear performance, conduct thickness measurement regularly, record the impact phenomenon of the elbow water hammer, and wear data, ultraviolet aging resistance of the elbow, the monitoring period is 3 months (20 measuring points, take the average value), and the recording results are shown in Table 3.

Table 3 Regular Test Data of the Test Elbow

|

Record Time |

2021 - 08 |

2021 - 11 |

2021 - 02 |

2021 - 05 |

2021 - 08 |

2021 - 11 |

2022 - 02 |

2022 - 05 |

2022 - 08 |

|

Elbow Wall Thickness |

6 . 02 |

6 . 00 |

5 . 96 |

5 . 95 |

5 . 90 |

5 . 88 |

5 . 85 |

5 . 83 |

5 . 78 |

Note: Elbow impact deformation: No; Surface cracking degree: Smooth, complete surface, no micro cracks.

In the same period, compared with the ordinary lining rubber elbow in the same working condition on the pipeline, it was found that it has been leakage problems caused by slurry erosion, but the test elbow has good appearance and normal wall thickness, as shown in Pic 3.

4.2 Economic Analysis

At present, the sales price of stainless steel pipe is in CNY30,000 ~ CNY40,000 / t, the sales price of rubber lining pipe is CNY30,000 / t. The wear resistance of UHMWPE is 5 ~ 6 times that of stainless steel pipe, the provisional comprehensive service life is 8 times that of stainless steel pipe, and the wear resistance is 8 ~ 10 times that of rubber lining pipe, the provisional comprehensive service life is 9 times that of rubber lining pipe, so the unit use efficiency of UHMWPE pipe per ton is equivalent to the use efficiency of CNY 160,000 stainless steel pipe and the use efficiency of CNY180,000 rubber lining pipe. At present, the sales price of UHMWPE pipe is about CNY 25,000 / t, which has a very high cost performance compared with similar products.

4.3 Other Application Advantages

4. 3. 1 Good Self-adaptability

In normal working condition, the slurry system has a great impact on the pipeline due to the change of medium flow, especially when the slurry door is closed, there is a strong water hammer phenomenon, which causes a great impact on the equipment, pipe, connection flanges and fasteners involved in the pipeline, and in serious cases the pipe will appear flange root crack, bolt fracture and other problems. UHMWPE pipe fittings have excellent impact absorption performance, the absorption value is the highest in all plastics, so the noise damping performance is very good, and it has an excellent noise reduction effect. At the same time, UHMWPE has extremely strong toughness, and its fracture elongation reaches more than 500%. For certain deviations, the pipeline system can be automatically repaired. If there are different pipe fittings or the size deviation of pipe structure due to construction problems, the corresponding deviation can be effectively compensated by its excellent elongation characteristics, and the cost of site transformation can be reduced.

4.3.2 Outstanding Self-cleaning Ability

UHMWPE, which is a kind of saturated carbon Hydrogen compounds, is holding a high chemical stability while a small surface tension, its surface adsorption force is very weak, less than 0.01%, and its surface hydrophobicity is good, so the other materials are not easy to adhere to the surface of this product.

4.3.3 Low Labor Intensity for Installation

The density of UHMWPE is about 1 / 8 of that of steel. An adult can easily pick up a UHMWPE straight pipe with DN 150 mm and WT 10 mm in a length of 6m (about 28 kg), while a steel pipe of the same size weighs 220 kg, which can only be lifted by mechanical equipment. During site installation, especially when high altitude installation and pipeline system staggered interference, using UHMWPE pipe fittings instead of traditional rubber lining pipe can greatly reduce the installation workload and installation difficulty, improve the installation efficiency, and improve installation safety for the work personnel on site.

5. Conclusion

Slurry pipe and pipe fittings are a part of the basic components of desulfurization system in thermal power plant. The rubber lining pipe is the main material in the early stage in domestic. With the disorderly development of the domestic pipeline lining rubber industry and the extensive development and application of other new materials, the use of high-tech materials in the desulfurization system is increasing day by day. During the selection of materials, the plant operator considered the cost performance and other factors through the engineering practice of the power plant, it proved that UHMWPE pipe fittings have high cost performance advantages compared with traditional rubber lining pipe, plastic lining pipe and alloy pipe, and also it has outstanding environmental performance while in line with the overall requirements of energy saving and consumption reduction advocated by the state. Domestic related industries and manufacturers are increasingly mature technology, the cost can be further reduced, it is worth to be vigorously promoted and applied for the electric power system.

Contact Us

Mobile/Wechat/WhatsApp: +86 188 6354 9177

Email: sales@dragonuhmwpe.com

Address: Xiangguang Economic Development Zone, Yanggu, Shandong, China

Postcode: 252300