UHMWPE dredge pipeline

DRAGON UHMWPE is specializing in the production of ultra-high molecular weight polyethylene(UHMWPE) pipes. Ultra-high molecular weight polyethylene (UHMWPE) is a kind of engineering thermoplastics with more than 1.5 million viscosity-average molecular weight.Ultra-high molecular weight polyethylene pipe has superior performance over

Keywords:

Classification:

Description

DRAGON UHMWPE pipe is made from Ultra High Molecular Weight Polyethylene with viscosity-average molecular weight of 2.0 million to 9.2 million g/mol.

Dragon UHMWPE manufacture the pipes with utilizing advanced extrusion technology.

DRAGON UHMWPE pipes have been widely applied in the fields of dredging, mining, chemical industry, power plant, water supply, food industry, conveyor systems, etc.

UHMWPE pipes size from DN 30 to DN1200

Characters of UHMWPE pipe:

High Wear Resistance

UHMWPE has the best wear resistance among all the engineering plastic.

UHMWPE pipes is 4~6 times more wear resistant than Q235 steel or 10 times that of HDPE pipes, which makes UHMWPE pipes works longer life under most operation conditions

Non-Scaling

With roughness of 0.00022mm, UHMWPE pipe is extremely smooth which provides UHMWPE Pipe far superior anti-scaling properties to any other pipeline on the market today.

It saved maintenance cost of acid cleaning pipes.

Along with the benefits mentioned above, UHMWPE Pipes also offer significant cost savings through increased pumping efficiency.

UHMWPE has a friction coefficient of 0.05, compared to 0.28 for HDPE or 0.58 for Steel (ISO 8295).

It means less friction, less pressure loss and greatly reduced energy inputs to deliver the same result.

With the same flow rate, UHMWPE pipe can save 25% energy

Extremely High Impact Resistance

UHMWPE pipe is greatly impact resistant which is 5 times that of HDPE pipe, 2 times that of PC pipe and 10 times that of PTFE pipes.

Chemical and Corrosion Resistance

With chemical resistance second only to PTFE (Teflon), UHMWPE pipe will offer superior life to other pipeline products in acidic or corrosive applications under 85 degrees C.

Environmental Friendly

Base material is colorless, odorless and non-toxic

Low carbon production process. The UHMWPE manufacturing process produces only 15% of the carbon dioxide emissions of that of the equivalent amount of steel pipe without discharge of waste water, exhausted gas and waste residue

Unique Patented Flanging System for UHMWPE stub connection

Well reputation Brand of UHMWPE pipes

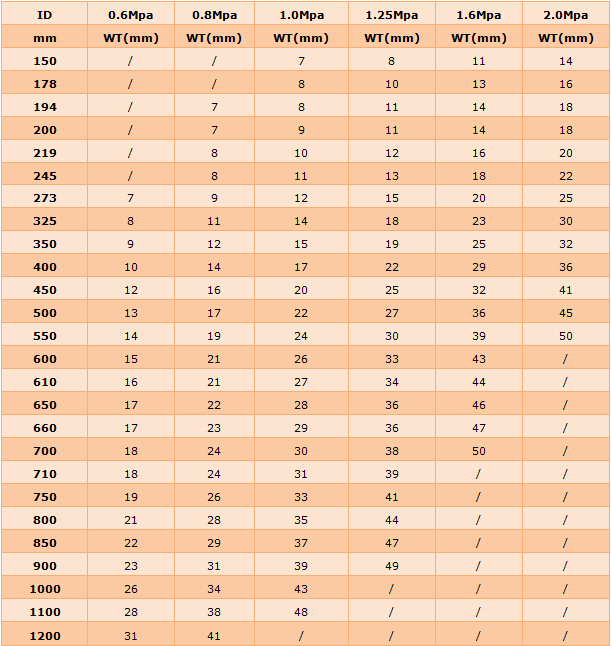

DRAGON UHMWPE Specifications

UHMWPE pipe DN 30- DN1200

Applications of DRAGON UHMWPE pipes

Mining

Mining pipes for Mineral sands mines; Mine Tailing lines; Mine concentration lines; Mineral mud conveying, Slurry transmission.

Dredging

Dredging pipe for dredging work, sediment transportation of the river, lake, sea port, wharf, etc

Power plant

Bottom and fly ash conveying of power plant, chemical water cycle and sulfur removal system

Chemical Industry

Transmission of high corrosive medium, like strong acid, strong alkali, etc and conveying of bittern, salt slurry, crude salt of salt chemical

Petrolchemical Pipelines

Transportation of crude oil and natural gas, waste water reinjection

Metallurgy Industry

conveying of coke powder, mineral powder, pulp and oil refining slag

Water Supply

Waste water and sewerage pipelines

Previous Article

Next Article

Previous Article

Next Article

Recommended Products

Contact Us

Mobile/Wechat/WhatsApp: +86 188 6354 9177

Email: sales@dragonuhmwpe.com

Address: Xiangguang Economic Development Zone, Yanggu, Shandong, China

Postcode: 252300