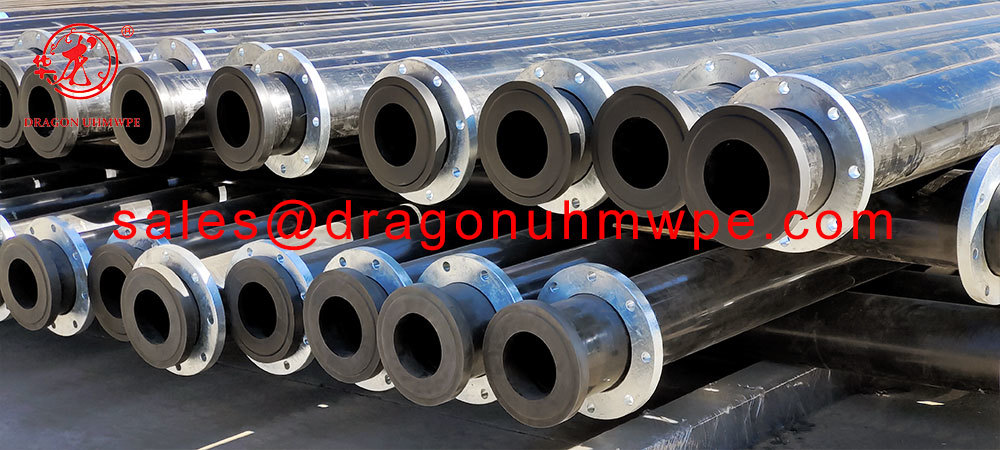

uhmwpe tailings pipeline

the combination of abrasion resistance, chemical resistance, low friction, lightweight, low maintenance requirements, and flexibility makes UHMWPE an excellent choice for tailings disposal pipelines.

Keywords:

Classification:

Description

uhmwpe tailings pipeline:

where there are differences, there is a market.

When it comes to transport mine tailings, Ultra-High Molecular Weight Polyethylene (UHMWPE) offers several advantages over other materials for tailings transport.

1. Chemical Resistance: UHMWPE is resistant to a wide range of chemicals, including acids, bases, and solvents. This resistance ensures that the pipeline can withstand exposure to various chemicals often present in mine tailings without degrading or corroding, enhancing its durability. Its chemical resistance is better than rubber/polyurethane/HDPE.

2. Abrasion Resistance: UHMWPE has exceptional resistance to abrasion, which is crucial for pipelines transporting abrasive materials like mine slurry. This property helps prolong the lifespan of the pipeline, reducing maintenance costs and downtime.

3.Low Friction Coefficient: UHMWPE has a very low coefficient of friction, its friction coefficient is lower than that of rubber/polyurethane/hdpe, which reduces the energy required for material transport. This property allows for smoother flow of tailings through the pipeline, reducing pumping energy requirements and operational costs.

4.anti-low temperature: uhmwpe property remains stable at minus 269 degress, according to survey to uhmwpe materials. This offer uhmwpe great advantage when applied at cold areas for outdoor slurry transport.

5.Lightweight: UHMWPE is lightweight compared to materials like steel, making it easier to handle, transport, and install. This characteristic can result in lower installation costs and faster deployment of the pipeline system.

6.Low Maintenance: Due to its inherent resistance to abrasion, corrosion, and chemical attack, UHMWPE pipelines typically require minimal maintenance compared to pipelines made from other materials. This results in reduced downtime and lower maintenance costs over the lifespan of the pipeline.

7.Flexibility: UHMWPE pipes are flexible, allowing them to withstand ground movements and thermal expansions without cracking or rupturing. This flexibility is particularly beneficial in environments where ground conditions are unstable or where the pipeline needs to navigate around obstacles.

Overall, the combination of abrasion resistance, chemical resistance, low friction, lightweight, low maintenance requirements, and flexibility makes UHMWPE an excellent choice for tailings disposal pipelines.

Previous Article

Next Article

Previous Article

Next Article

Recommended Products

Contact Us

Mobile/Wechat/WhatsApp: +86 188 6354 9177

Email: sales@dragonuhmwpe.com

Address: Xiangguang Economic Development Zone, Yanggu, Shandong, China

Postcode: 252300