uhmwpe dredge pipe

uhmwpe pipe for sediment, sand dredging

Keywords:

Classification:

Description

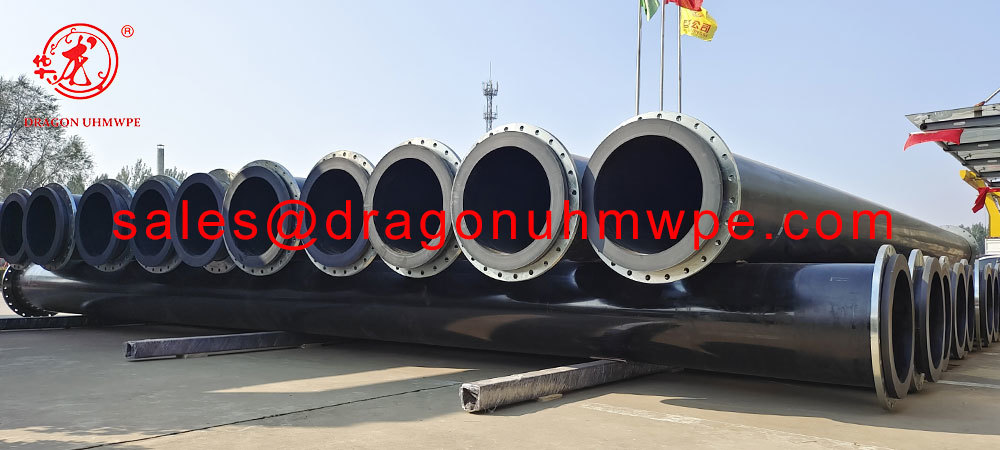

Dredge pipes are critical components in dredging operations, which are carried out to remove sediment, sand, and debris from the bottom of lakes, rivers, harbors, and other water bodies. The types of dredge line available in the market vary based on material, size, application, and specific design features. They are also called Slurry pipe, dredge tube. Here’s an overview of the common kinds:

1. HDPE Dredge Pipes

Material: High-Density Polyethylene (HDPE)

Features: Corrosion-resistant, lightweight, flexible, and durable. These are widely used due to their ease of handling and resistance to wear and chemical attack. They are often used for discharging dredged material.

2. UHMWPE Dredge Pipes

Material: ultra-high molecular weight polyethylene (UHMWPE)

Features: More Corrosion-resistant, better anti-abrasion, lightweight, flexible, and durable. These are widely used due to their ease of handling and resistance to wear and chemical attack. They are often used for discharging dredged material.

3. Steel Dredge Pipes

Material: Steel (can be carbon steel, stainless steel, or coated steel)

Features: Extremely durable and resistant to high pressure and impact. Steel pipes are suitable for heavy-duty applications but are heavier and require corrosion protection treatments.

4. Rubber Dredge Pipes

Material: Rubber or rubber-lined materials

Features: Excellent flexibility, wear resistance, and the ability to handle large particles. They are mainly used as discharge hoses and are prized for their ability to absorb vibrations and shocks.

5. Composite Dredge Pipes

Material: Combination of materials such as fiberglass and resin

Features: Offer a balance between weight, strength, and corrosion resistance. They are used in both suction and discharge applications where a lighter alternative to steel is desirable but with better durability than HDPE.

6. PVC Dredge Pipes

Material: Polyvinyl Chloride (PVC)

Features: Lightweight, resistant to chemical erosion, and relatively low in cost. Suitable for smaller-scale or temporary dredging operations.

7. Flexible Dredge Pipes

Material:: Can be made from flexible versions of HDPE, rubber, or other synthetic materials

Features: Highly adaptable and can be used in situations where rigid pipes are not suitable. They are excellent for applications requiring movement or bending around obstacles.

8. Ceramic-Lined Dredge Pipes

Material: Typically steel or HDPE pipes with a ceramic lining

Features: Combines the strength of steel or the flexibility of HDPE with the abrasion resistance of ceramics. Ideal for highly abrasive environments.

Considerations for Selection

The choice of dredge pipe depends on several factors, including the nature of the material being dredged, the distance over which it will be transported, the environmental conditions (such as the presence of corrosive materials), and the project budget. For instance, HDPE pipes are chosen for their combination of flexibility, wear resistance, and cost-effectiveness in many scenarios, while steel pipes might be selected for their durability and strength in more demanding operations.

Dredge pipes also come in various diameters and lengths, with connections and fittings designed to handle the specific demands of dredging operations, such as quick coupling systems for easy assembly and disassembly.

Previous Article

Next Article

Previous Article

Next Article

Recommended Products

Contact Us

Mobile/Wechat/WhatsApp: +86 188 6354 9177

Email: sales@dragonuhmwpe.com

Address: Xiangguang Economic Development Zone, Yanggu, Shandong, China

Postcode: 252300