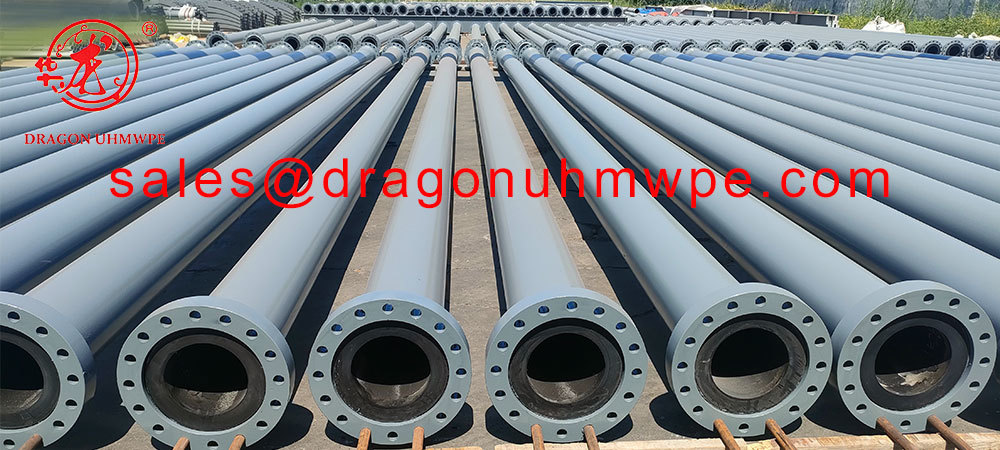

PE UHMW lined pipe spools for tailings slurry transport

PE UHMW lined steel spool is made of UHMWPE pipe and carbon steel pipe. Its outer layer is the steel pipe with flange as the pressure standing protective layer, UHMWPE pipe is lined inside as wear layer, anti corrosive pipe with extremely smooth surface. The inner UHMWPE pipe is extended out of the outer layer of carbon steel pipe and flanged as connection of pipe.

Keywords:

Classification:

Description

What is UHMWPE

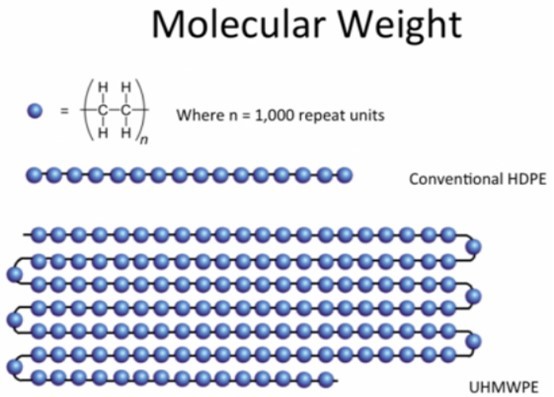

UHMWPE,ultra-high molecular weight polyethylene, is defined by ISO21304-1:2019 as polyethylene materials having a melt-flow rate (MFR) of less than 0.1g/10min, measured at 190℃ and 21.6 kg load. UHMWPE, is linear structure of polyethylene polymer with an viscosity molecular weight of 2,000,000, as defined by China standard QB/T2668.1-2017. This molecular weight is well above the molecular weight of most typical polymers which are between 100,000 and 400,000. Thus earning the title Ultra-high molecular weight polyethylene.

With high molecular weight,UHMWPE is excellent engineering thermoplastic with extraordinary performance. It combines almost all virtues of various plastic together and with advantages of wear resistance, corrosion resistance, impact resistance, self lubrication, low friction loss, non scaling, low temperature resistance, health non-toxic, non-adhesive, non-absorbency which makes UHMWPE prior to other engineering plastics.

UHMWPE Pipes

UHMWPE pipes are extruded with UHMWPE resin of which the viscosity molecular weight above than 2,000,000. The higher the molecular weight is, the more wear resistance UHMWPE pipe is, and the more difficult to be extruded out.

Dragon UHMWPE pipes, extruded with UHMWPE resisn of which the viscosity molecular weight between 3,000,000 - 3,500,000.

Properties of UHMWPE pipes:

Properties of UHMWPE pipes:

Wear resistance: UHMWPE pipes have excellent wear resistance providing long life in abrasive slurry pipeline applications.

Chemical resistance: the outstanding resistance to wide range of chemical reagents, allows the application of UHMWPE pipes in tailing pipelines and chemical treatment applications used in mining operations.

Lower pumping cost due to superior smooth surface and less friction loss. Surface roughness of UHMWPE pipe lies in between Ra 0.16~0.22 um. Less friction, less pressure loss and greatly reduced energy inputs to deliver the same result.

Easy installation: UHMWPE pipes are easy to be installed because of light weights and flanged stubs.

Dragon PE UHMW lined pipe spools for tailings slurry transport:

UHMWPE is lined into steel pipe through shrinkage technology for a tight fit. Steel pipe is the outer layer for pressure holding, UHMWPE as the inner liner layer to provide longer life for wear process.

Sealing face is UHMWPE stub, which is made through flanging heating to UHMWPE liner pipe itself.

Connection between pipes is through UHMWPE stub sealing face and steel flanges.

Performance of UHMWPE lined spools:

High pressurre holding capacity.

Abrasion resistance.

Impact resistance.

Anti corrosion

Less friction loss.

Dragon UHMWPE lined steel pipe specification:

| Diameter | DN100 to DN1200 |

| uhmwpe liner wall thickness | 6mm to 40mm |

| Length | 5.8m or 11.8m or customized length |

| Steel pipe Material Grade | Q235/C20/C45/API5L Gr.B/X42 to X70 Steel |

| UHMWPE liner material grade | 3,000,000 ~3,500,000 molecular weight UHMWPE |

| Outer painting | Acrylic paint for anti-corrosion |

| Connection | Steel flanges |

Application of Dragon uhmwpe lined pipe spools:

Transportation pipeline for mine slurry, tailings, sediments and ore concentrates;

Transporta pipeline for coal fly ash water slurry;

Chemical and corrosive fluid, brine water transmission.

Previous Article

Next Article

Previous Article

Next Article

Recommended Products

Contact Us

Mobile/Wechat/WhatsApp: +86 188 6354 9177

Email: sales@dragonuhmwpe.com

Address: Xiangguang Economic Development Zone, Yanggu, Shandong, China

Postcode: 252300