Wear Resistance UHMWPE Rods

Ultra-high molecular weight polyethylene (UHMWPE) is a kind of engineering thermoplastics with more than 3 million viscosity-average molecular weight. It differs from PE standard grades in its very high degree of polymerization. Ultra-high molecular weight polyethylene pipe has superior performance over conventional HDPE pipe such as very high wear resistance, impact resistance, intrinsically self-lubricating, anti-adhesion, low temperature resistance and excellent chemical resistance.

Keywords:

Classification:

Description

| Description |

Ultra-high molecular weight polyethylene (UHMWPE) is a kind of engineering thermoplastics with more than 3 million viscosity-average molecular weight. It differs from PE standard grades in its very high degree of polymerization. Ultra-high molecular weight polyethylene pipe has superior performance over conventional HDPE pipe such as very high wear resistance, impact resistance, intrinsically self-lubricating, anti-adhesion, low temperature resistance and excellent chemical resistance.

UHMW is more rigid than LDPE and HDPE, and has better abrasion resistance than PTFE.

Can be widely used in metallurgy, mining (mineral mud conveying, backfilling by grouting ),power (fly ash conveying), sand dredging pump (lake dredging mud conveying, sand pump pipe of pumping vessel), oil, natural gas, textile, papermaking, food, chemical, mechanical, electrical and other industries.

| Features |

UHMWPE Rod Main characteristics:

1. Very high-wear resistance, seven times wear resistance than steel, four times than PTFE.

2. Very high anti-impact resistance, two times impact resistance than PC, five times than ABS.

3. Good self-lubrication, the same as PTFE, better than steel and brass appended lubricating oil.

4. Good anti-corrosion resistance, it has very stable chemicals property and can endure the corrosion of all kinds of corrosive medium and organic solvent in certain rang of temperature and humidity.

5. Very high-inadhesion resistance, the surface of product hardly affixes other material.

6. Very high-impact resistance, ten times impact resistance than PA66, eight times than PTFE.

7. Good low temperature resistance, in liquefied nitrogen (- 196), it still has the prolongation.

few other materials can reach to this performance.

8. Non-toxic and clean property, UHMW-PE, which is the material that Food and Drug Administration (FDA) and United States Department of Agriculture (ASDA) permit to apply in food and medicine fields.

| Specifications |

Performance of UHMWPE Rod

| Test items | Unit | Results | Test basis |

| Tensile yield strength | Mpa | 34.9 | GB/T 1040-2006 |

| Tensile breaking strength | Mpa | 38.8 | GB/T 1040-1992 |

| IZOD Impact strength | KJ/m2 | 137 | GB/T 1843-1996 |

| Elongation(sample size :80*10*4mm) | % | 318 | GB/T 1034-1998 |

| Heat Deflection Temperature | ℃ | 96 | GB/T 1663-2000 |

| Melt Temperature | ℃ | 236 | GB/T 1634-2001 |

| Coefficient of friction | --- | 0.01 | GB/T 0006 -2002 |

| Ball indentation hardness | N/mm2 | 42.3 | GB/T 3398-1982 |

| Density | g/cm3 | 0.96 | GB/T 1033-1986 |

| Application |

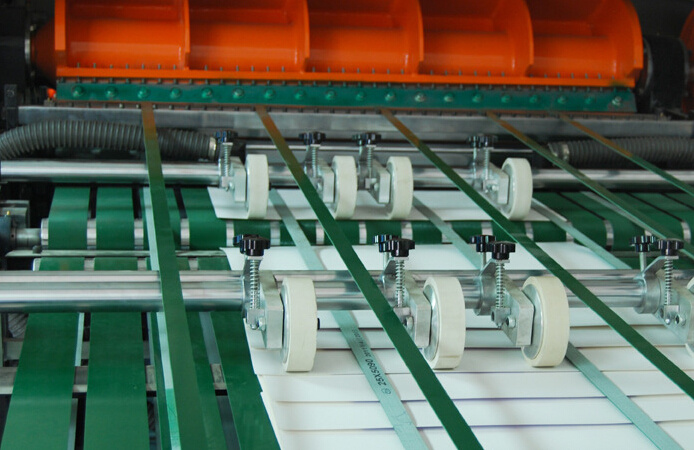

1. Paper making industry: with its performance of high wear resistance and good self-lubrication, can be used in: vacuum box panel, dehydration plank, drawknife, pressurize assembly, shaft sleeve of paper-cutting machine and so on. The thickness of UHMW-PE tube below 10mm, can be made into covering tube of strap transport and transcribing machine roller.

2. Food and beverage light industry: with its performance of high wear resistance, anti-impact resistance, inadhesion resistance, non-toxic and clean property, can be manufactured: moving plate, transport screw, gear and so on, which is easy-cleaning, long-enduring, and anti-mildew,

and be used in other clear parts.

3. Waste-water industry:

Polluting mud scraping plate of helix transportslurry pump impellerpump bearing bushgrit collection systemdefecator gearprecipitation pool scaleboard and so on.

4. Electronic Industry: Surface dealing of semiconductor process, air-pollution control system, waste-water vent control and so on. UHMW-PE, has the excellent Performance of

low-temperature resistance, which has a good ductibility in the

Liquefied helium (-269), was started to apply in the refrigeration technology and low temperature field. The latest UHMW-PE tube can be applied in semiconductor field instead of a great deal of PTFE tubes.

5. Textile industry: With its performance of high-wear resistance, anti-impact and good self-lubrication, the products, such as: strap knot, gear, cushion baffle, bearing bush and so on.

6. Sport and amusement industry: ski tools lining, assembly of track vehicle in ice and snow, earth plate of glider plane, assembly of steel ball equipment, shaft sleeve of all size, rolling ball path, accessory of mechanization sledge and so.

7. Medical industry: Body embedded substance, artificial joints, rectifying surgical machine and bracket, orientation rack of surgical machine.

Chemical and other industry: galvanization hardware, agricultural machine, shipping parts, mechanical parts of low-temperature atomic energy and so on. Mostly using of its high-wear resistance, high anti-impact resistance, anti-cold resistance, self-lubrication, electric characteristic.

Previous Article

Next Article

Previous Article

Next Article

Recommended Products

Contact Us

Mobile/Wechat/WhatsApp: +86 188 6354 9177

Email: sales@dragonuhmwpe.com

Address: Xiangguang Economic Development Zone, Yanggu, Shandong, China

Postcode: 252300