UHMWPE dredging pipe

DRAGON UHMWPE pipe is made from Ultra High Molecular Weight Polyethylene with viscosity-average molecular weight of 2.0 millioin to 9.2 million g/mol.

Keywords:

Classification:

Description

Wear resistant UHMWPE dredging pipe

DRAGON UHMWPE pipe is made from Ultra High Molecular Weight Polyethylene with viscosity-average molecular weight of 2.0 millioin to 9.2 million g/mol.

We manufacture the pipes with utilizing advanced extrusion technology.

DRAGON’s UHMWPE pipes have been widely applied in the fields of dredging, mining, chemical industry, power plant, water supply, food industry, conveyor systems, etc.

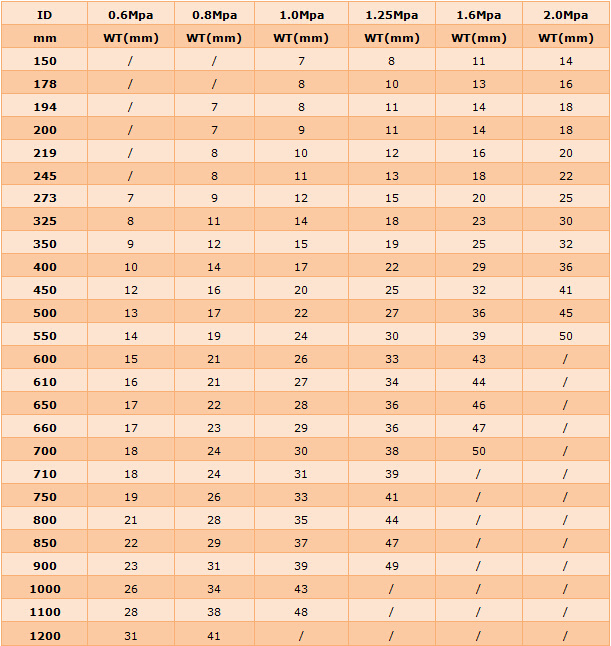

Diameter: ID 30 to ID 1200mm

Thickness: 3.5mm to 65mm

Length: 5.8m or 11.8m or customised length but suitable for transportation

For wear process, please inquire us to get right ID and thickness

Working pressure and required wear layer is basic requirement for thickness design.

Features:

High wear resistance

The wear resistance is 3 to 7 times of Q235 steel pipe or PE100 pipe

Which means :Longer Working life, Less Maintainence cost and Less downtime for pipe replacement and rotation

Extremely Smooth

Surface roughness of UHMWPE pipe is 0.00022mm superior to PTFE (Teflon).

UHMWPE has a friction coefficient of 0.05 compared to 0.28 for HDPE or 0.58 for steel (ISO 8295)

For its Extremely smooth surface, UHMWPE pipe has far superior anti scaling property to any other pipelines on the market currently.

High impact strength, flexible and light

UHMWPE is 5 times of oridinary PE pipes, 4 times than HDPE, 2 times of polycarbonate pipe, and 10 times of PTFE pipe.

It means easy installation and less installation cost

High corrosion resistance

For its saturated molecular structure, it has high chemical stability, resistance to all kinds of corrosive medium (acid, alkali, salt) and organic solvent.

It will offer longer life than other pipelines in acid or corrosive applications.

Unique Australian Flanging Technology

We used our Australian partner's automated flanging technology.

It is unique in the UHMWPE world which results in significant performance benefits.

Consistent and better than everyone else flanging quality, Fast, safe and efficient production.

DRAGON UHMWPE Dredging pipe

Key Applications:

transmission of slurry in mining

mineral sands, mining tailings, mine concentration

dredging: fine sand, coral sand, mud, dredging, reclamation, marine construction,

Power plant

flying ash, bottom ash slurry, brine water

Chemical industry

corrosive water, sewage water

Previous Article

Next Article

Previous Article

Next Article

Recommended Products

Contact Us

Mobile/Wechat/WhatsApp: +86 188 6354 9177

Email: sales@dragonuhmwpe.com

Address: Xiangguang Economic Development Zone, Yanggu, Shandong, China

Postcode: 252300